-

General Pumps

- Titanium pumps

- Air Operated Double Diaphragm Pumps

- Magnetic Drive Pumps

- Barrel Unloading Pumps

- Self Priming Pumps

- Gear Pumps

- Lobe Pumps

- Centrifugal Process Horizontal Pumps

- Vertical Sump Pumps (Cantilever Type)

- PVDF and PTFE Lines Centrifugal Pumps

- Dewatering Pumps - Submersible

- Metering - Dosing Pumps

-

Other Products

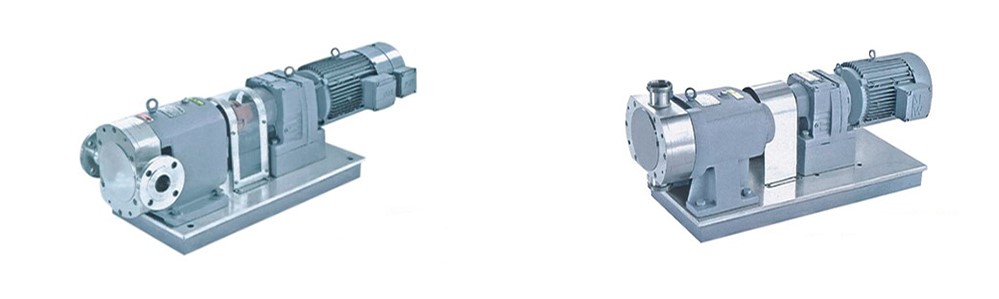

Lobe Pumps

The RHODEK rotary lobe pump basically consists of two lobe rotors which rotate inside the casing without touching each other. As the rotors rotate, the space between the lobes and the casing is successively filled with the product which is driven to the discharge nozzle displacing a fixed amount of product. The pumped product forms a continuous stream due to the adjusted tolerances of the lobes and the pump casing thus ensuring an efficient pumping.

Pump Technical Details

| Model | Displacement (L/r) | Rotation speed (r/min) | Flow rate (M³/h) | Dis. Pre. (Mpa) | Electrical power (Kw) | Suc. Pre. (Mpa) | Dia. of inlet and outlet (mm) |

|---|---|---|---|---|---|---|---|

| 25BV6 /12-2 | 0.15 | 20-600 | 2 | 0.1-1.2 | 1.1-2.2 | -0.095 | 25 |

| 40BV6 /12-5 | 0.32 | 20-550 | 5 | 0.1-1.2 | 1.5-4 | -0.095 | 40 |

| 50BV6 /12-10 | 0.65 | 20-550 | 10 | 0.1-1.2 | 2.2-7.5 | -0.095 | 50 |

| 65BV6 /12-20 | 1.74 | 20-550 | 20 | 0.1-1.2 | 4-15 | -0.095 | 65 |

| 80BV6 /12-30 | 2.48 | 20-550 | 30 | 0.1-1.2 | 5.5-22 | -0.095 | 80 |

| 80BV6 /12-40 | 3.65 | 20-550 | 40 | 0.1-1.2 | 7.5-30 | -0.095 | 100 |

| 125BV6 /12-50 | 4.60 | 20-550 | 50 | 0.1-1.2 | 11-45 | -0.095 | 125 |

| 125BV6 /12-70 | 6.10 | 20-550 | 70 | 0.1-1.2 | 15-55 | -0.095 | 125 |

| 125BV6 /12-80 | 7.63 | 20-550 | 80 | 0.1-1.2 | 18.5-75 | -0.095 | 125 |

| 150BV6 /12-120 | 11.56 | 20-420 | 120 | 0.1-1.2 | 22-90 | -0.095 | 150 |

| 150BV6 /12-150 | 14.22 | 20-420 | 150 | 0.1-1.2 | 37-110 | -0.095 | 150 |

| 200BV6 /12-200 | 18.10 | 20-420 | 200 | 0.1-1.2 | 45-132 | -0.095 | 200 |

| 250BV6 /12-250 | 22.92 | 20-420 | 250 | 0.1-1.2 | 55-160 | -0.095 | 250 |

| 300BV6 /12-300 | 32.00 | 20-420 | 300 | 0.1-1.2 | 75-200 | -0.095 | 300 |

Design and Features

- Vertical support

- Bare-shaft construction

- Self-drainable pump

- Tri-lobe rotors

- Hygienic design of the attachment of the lobes

- Sanitary mechanical seal, internal assembly

- The seal is disassembled from the frontal part without disassembling the casing of the pump. Gaskets with deformation limiters prevent any dead leg

- Easy cleaning and maintenance

- Standard connection : clamp

- Pump certified according to the EHEDG standards

Materials

- Investment casting casing and lobes : AISI 316L

- Ball bearing support GG-25

- Gaskets : EPDM according to FDA 177.2600

- Mechanical seal : SiC/C/EPDM

- Internal surface finish : Ra ≤ 0,8µm

- External surface finish : bright polish

Options

- Mechanical seal: SiC/SiC, TuC/SiC

- Flushed or balanced mechanical seal

- Gaskets: FPM or FFPM

- Bi-wing lobes. Relief valve or external by-pass

- Heating jacket

- Ra ≤ 0,5 μm surface finish for pharmaceutical applications

- Horizontal assembly (no EHEDG certificate)

- Various types of drives and protections (gear motor with frequency converter, etc.)

- Assembly on a 304 stainless steel baseplate on silent-blocks, sanitary design

- Trolley and control panel

- Connections: Clamp DIN32676, DIN 11864-1, DIN 11864-2, etc.

- Material certificates (3.1), roughness certificate

- The pump can be ATEX certified