Centrifugal Process Pumps - Horizontal metallic type

We are one of the most recognized names engaged in offering metallic pumps which are widely demanded in the industry. Each of the product delivers peak performance ,efficient ,easy to handling and maintenance.

We offer metallic pumps in following MOC's:

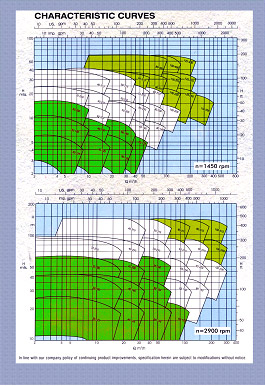

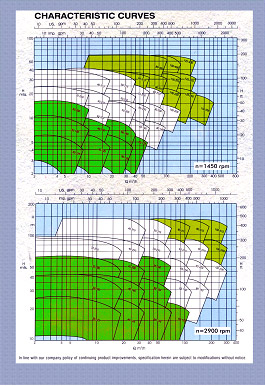

Range Of Product:

Capacities

– Up to 1200 M3/HR

Head

– Up to 145 Meters

Temperatures

– Minus 40°C to Plus 300°C

Design Features:

All The Wetted parts Are Made From Investment Castings Using Lost Wax process, Giving Excellent Surface Finish, Sound Castings, Giving Minimum Resistance to Flow Resulting in better Efficiencies.

All centrifugal process pumps are of single stage, horizontal end suction type, with semi open and closed impellers. The semi open impellers are used / supplied where liquids, containing solids, or have a tendency to polymerize or crystallize. A special feature is easy of maintenance due to the foot mounted volute casing, permitting removal of the rotating assembly without disturbance of pipe connections. An extensive choice of materials of construction is offered enabling a wide range of chemicals to be handled. The casing assembly is hydrostatically tested to a minimum of 1.5 times the shut-off pressure.

Additional non-destructive testing procedures are carried out as standard practice on all pump parts

Impeller :

Impellers are of the Semi open and closed in Design. They are statically and hydraulically balanced. Semi open Impellers have integral cast back vanes to provide hydraulic balance and relieve stuffing box pressure. They are located on the shaft by a incorporating a screw threads and sealed against the shaft by PTFE 0" rings.

Sealing:

Our Pumps are supplied with gland packing or mechanical seal in the stuffing box with connection for sealing and flushing liquid. Design incorporates a lantern ring and gland which enables easy changing of the gland packing without dismantling the pump. The stuffing box is designed so that mechanical seals can be fitted with little or no alteration.

Steam Jacketed Pumps :

Our pumps can be supplied with stem jacketed casing for handling liquids which solidify at ambient or above ambient temperatures. The jacketed casing is used with the jacketed stuffing box to provide a completely heated liquid end. This construction easily handles high melting liquids such as sulphur, naphthalene, tars, waxes, etc.

Applications: