Design features

Polypropylene Pumps are specially design for highly corrosive chemicals in which metal pumps are not recommended or in its cost is higher. The PP pumps design are single piece molded polypropylene volute casing with semi-open impeller and casing cover to ensure a smooth running performance against corrosion. The high alumina ceramic sleeve protects shaft to any corrosion and abrasion. The GFT or Sic Vs. Ceramic PTFE below Mechanical seal prevents the leakage from the pumps. The Cast Iron heavy duty oil lubricated bearing housing provides maximum strength to pump.

Industries

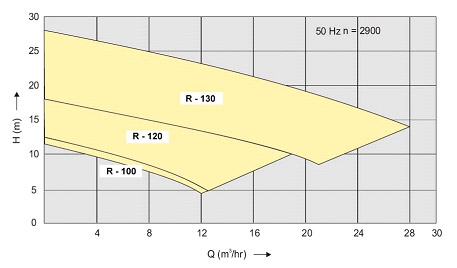

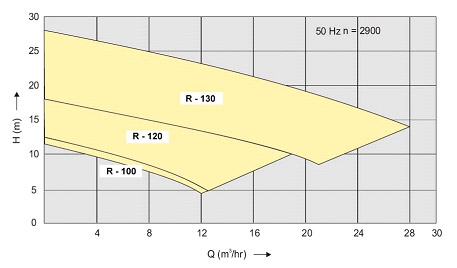

R –I Series – Models available R-100, R-120, R-130

Technical Details

| Model |

Suction MM |

Delivery MM |

Impeller Dia In MM |

HP |

Rpm |

| R – 100 |

25 |

25 |

100 |

1 |

2900 |

| R – 120 |

40 |

40 |

120 |

2 |

2900 |

| R – 130 |

50 |

40 |

130 |

3 |

2900 |

Performance Chart

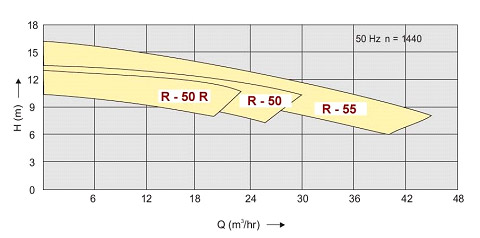

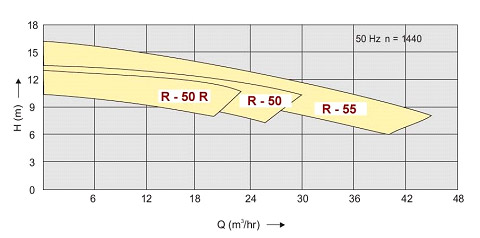

R –II Series – Models available R-50R , R-50, R-55

Technical Details

| Model |

Suction MM |

Delivery MM |

Impeller Dia In MM |

HP |

Rpm |

| R – 50 R |

75 |

40 |

210 |

3 |

1440 |

| R – 50 |

40 |

40 |

205 |

2 |

1440 |

| R – 55 |

50 |

40 |

210 |

5 |

1440 |

Performance Chart

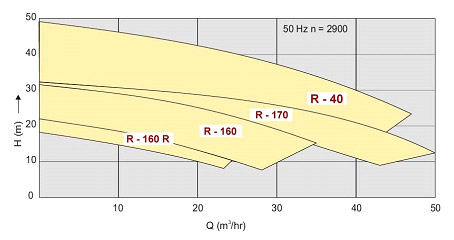

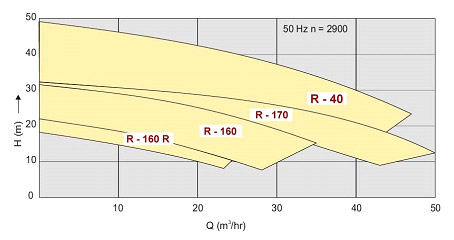

R –III Series – Models available R-160 R , R-160, R-170, R – 40

Technical Details

| Model |

Suction MM |

Delivery MM |

Impeller Dia In MM |

HP |

Rpm |

| R – 160 R |

40 |

40 |

150 |

3 |

2900 |

| R – 160 |

75 |

40 |

160 |

5 |

2900 |

| R – 170 |

75 |

50 |

160 |

7.5 |

2900 |

| R – 40 |

50 |

40 |

190 |

10 / 12.5 |

2900 |

Performance Chart

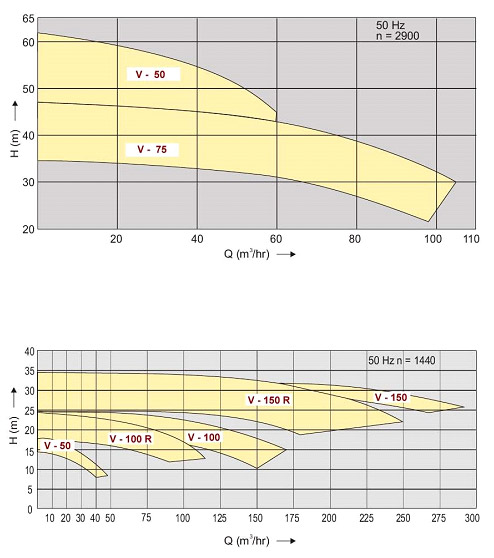

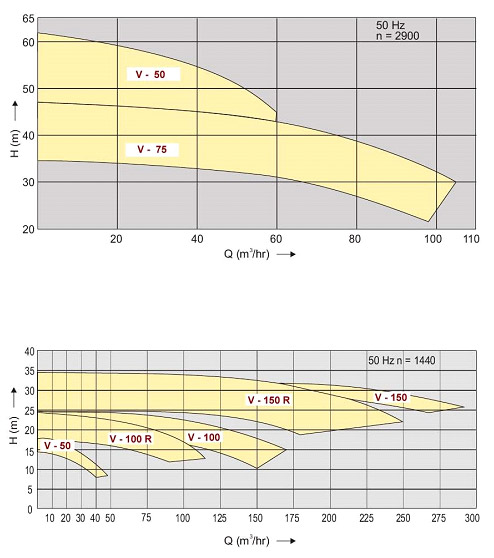

V Series – Models available V-50 , V-75, V-170, V –100,V-100 R , V-150 , V-150R

Technical Details

| Model |

Suction MM |

Delivery in MM

|

| V –50 |

50 |

50 |

| V –75 |

150 |

100 |

| V –100 |

100 |

75 |

| V –150 |

150 |

100 |

Performance Chart